Meet the people behind the products. From semi-conductors to Jet engine turbines – from apple pie filling to smoked salmon – from cosmetics to high definition micro displays – Council members make the products that make the world run. Through our podcast we introduce listeners to the people who own, work in, and support these businesses, businesses that together are the Council of Industry. We learn about their products and career paths. We learn about their leadership styles and their passion for their work. We learn about their challenges and their opportunities. In the process we learn more about manufacturing and why it is such a vital sector of our economy- vital to our region’s prosperity, our security and our future.

Issue: 2020 Fall

The Opportunity Ecosystem

EDUCATION AND WORKPLACE

FUTURE OPPORTUNITIES | Dr. Michael A. Baston, President

When Elisabeth Kübler-Ross, in her 1969 book, On Death and Dying, proposed the five stages of grief and loss, she could not have foreseen the myriad challenges 2020 would present our region, our nation, and our world.

Although those who are grieving do not necessarily go through the stages in the same order or experience all of them, in many ways, and for a multitude of reasons, we all have been impacted by the confluence of COVID-19, its resultant economic upheaval, and structural racial issues which have created a “perfect storm.” Some are in the stages of denial and isolation or anger. Others are in the bargaining or depression stages. I would argue, however, that we must move to the acceptance stage.

We must accept the death of outdated thinking that has, for far too long, hindered the limitless growth potential of all people, particularly given the historical realities of bigotry, prejudice, discrimination, and inequity in all forms, both institutional and individual. We must accept the death of the misconception that college should be limited to the privileged few or that the community college is in some way “inferior.” We must accept the death of the notion that colleges should sanction directionless wandering instead of placing greater emphasis on career development and exploration, values formation, citizenship, and a respect for the dignity of work – foci that have been considered by some in academia of lesser value than allowing students to use college to “find themselves.”

Regional survival of the effects of the perfect storm, while an ideal goal, is an anemic aim. Working together, partners in government, educational institutions, business, industry, and community-based organizations, leaders can address inequities, promote educational opportunities, and ensure economic recovery – even in a pandemic, if we reimagine the opportunity ecosystem in the Hudson Valleys of our nation. A commitment to inclusive excellence, educational access, programmatic diversity, and the alignment of work and learning is required.

COMMITMENT #1 – INCLUSIVE EXCELLENCE

Hard realities exist. Structural racism, based on historical policies and practices and its subsequent inequitable outcomes in economic wealth, health, education, and life expectancy, has not yet been fully dismantled. Implicit bias—the unchallenged narratives and assumptions about historically marginalized people—is insidious and is still today often unrecognized by well-meaning people. We, however, do not have to accept that these realities cannot be addressed. We must reassert our commitment toward eradicating racism and supporting social justice, and, more importantly, set forth a strategy to effect reform and achieve inclusive excellence so that the workforce of tomorrow is stronger. Our workforce needs not only to have the knowledge and skills necessary to move forward, but the equal footing that will allow everyone’s talents to rise to the top so they can become their best version of themselves.

I understand that the challenge is great, but the potential of our people is even greater. I am a community college president in the eye of the storm, but we have not shrunk from the enormity of the moment because of the size of the task. Community colleges have always reflected the American promise of education – equal access and equal opportunity – to offer a beacon of hope to those who strive to improve their lives. Our current global crisis has strengthened our collective resolve and refocused our mission to keep that beacon shining brightly, leading us all safely into a better, more equitable world. But, as they say, talk is cheap—we must commit to taking steps beyond statements to achieve any lasting change. Here is how we can do that from the community college perspective, which can be replicated by others in our opportunity ecosystem, including business and industry.

We began developing an actionable plan at RCC last June. We established The Steps Beyond Statements Working Group to review the legacy of diversity efforts led by the College’s former Diversity Committee to build on their outcomes to reflect current realities. The group has been charged with developing a new college-wide plan with specific outcomes that are measurable, using key performance indicators to be reported in an equity scorecard, including:

- Conducting an institutional self-assessment on equity practices.

- Developing equity practice expectations in the non-academic spaces of the college.

- Identifying campus-based and external experts with experience in helping faculty and staff better understand diversity, equity, and inclusion space issues.

- Creating a comprehensive process for monitoring, reviewing, and updating the equity scorecards and related activities.

Whatever the field of endeavor, statements in opposition to structural racism, hatred, and bigotry must be followed by steps that evidence the true nature of our commitment. What we do speaks much louder than what we say. Inclusive excellence must be a priority of all the members of Hudson Valley’s opportunity ecosystem.

COMMITMENT #2 – EDUCATIONAL ACCESS AND PROGRAMMATIC DIVERSITY

Another hard reality is that community colleges have gotten a bad rap, mostly from those who have never been to one.

Community Colleges are not “safety school” options. Rather, community colleges are a strategic choice for families, particularly given COVID-19 and the nation’s current economic uncertainty.

Our campus is open to everyone. Many RCC grads have gone on to graduate from Yale, Brown, and other prestigious institutions.

Indeed, nearly half of all bachelor’s degree earners in the United States have attended community colleges at one time or another, and the pandemic is proving just how valuable our institutions are to the entire educational ecosystem. Community colleges not only provide a quality, affordable education close to home, but we also play an essential role for individuals looking to retool and retrain for new careers as the workforce landscape changes in this time of uncertainty and as we navigate a culture change as a nation. Our programmatic diversity, given our cost, is unparalleled.

While students need to be ready for college, we understand it is just as important for colleges to be “student-ready” — meeting students where they are and offering career options that match their needs and desires to the jobs that are and will be available.

RCC is at the forefront of developing skill-specific programs. In addition to two-year degrees in business, education, and nursing programs, RCC’s Career Skills Academy was established last year to offer skill-specific programs to fill “middle-skills” jobs—those who require more education and training than a high school diploma but less than a four-year college degree and which pay a familysupporting wage. Our Career Skills Academy provides work-ready programs for students of any age to gain the necessary skills for a new job or enhance an existing career. The programs are designed to teach specific skills in a concentrated time frame so students can start a new career, earning a good salary in just a few weeks or months. Classes in IT support, computer-assisted design, social media branding and marketing, professional bookkeeping, medical call center customer service, gas pipeline operations, and more are available.

COMMITMENT #3 – WORK AND LEARNING ALIGNMENT

A final hard reality, we can no longer allow a disconnect between education and career trajectory to exist if the nation is to retain its competitiveness globally. The future of work and learning are intertwined, and we remain steadfast in our goal of building bridges to mobility, opportunity, and success. Career pathways matter, particularly now as critical industries like advanced manufacturing, have emerging opportunities that will require an educated and skilled workforce.

RCC’S partnership with T-SEC, The Strategic Economic Consortium, has made a significant difference. The partnership helped to develop, inform, and support Career Skills Academy offerings, particularly for the Advanced Manufacturing sector, the Assistive Technology, and Healthcare sector, and the Auto industry sector. RCC has a T-SEC funded 3D print lab at our Haverstraw extension campus, making access to and training on the technology available to educators, students, and the regional manufacturing and business communities.

Currently, the print lab works in partnership with Helen Hayes Hospital’s Physical Therapy division to prototype several different assistive technology devices, such as a utilitarian joystick.

To reimagine the opportunity ecosystem a commitment to inclusive excellence, educational access, programmatic diversity, and the alignment of work and learning is required.

The RCC Hospitality and Culinary Arts Center was established in response to the burgeoning growth in restaurants and tourism in the Hudson Valley and the resulting need for more qualified workers. It offers fasttrack culinary arts certificate programs. Housed in the same location as Hudson Market on Main, a collaborative effort between Flik International and RCC, students contribute to the daily menu offerings of the Market and prepare packaged and canned items to understand marketing and selling in a retail environment. The Center will also offer students an opportunity to operate their own pop-up restaurant when the window for that opportunity is once again safe, providing them with real-world experience that will launch them into careers in the culinary arts at all levels. When colleges, businesses, and industry partner, the community wins. The economic vitality of a community is inextricably tied to multiple stakeholders working together to ensure that opportunity exists for all.

CONCLUDING THOUGHTS

As we navigate this perfect storm and move through today’s choppy waters with its hard realities, we must have high hopes. For our part, RCC moves forward with the steadfast goal of supporting students today to make a better life for themselves and their families tomorrow. We do so with the knowledge that we can set the standard for providing quality career options for learners of all levels and all ages. We do so with pride, knowing we are shattering the misperceptions about community colleges. We move forward into the dawning of a new era, one that can and will offer inclusive and equitable options for all.

Dr. Michael A. Baston, President, Rockland Community College.

Named as one of the country’s most Notable Education Leaders of 2017 by Diverse: Issues in Higher Education. Author of The Handbook for Student Affairs in Community Colleges.

Resource Guide Fall 2020

FEDERAL ELECTED OFFICIALS

PRESIDENT

DONALD J. TRUMP (R)

Capitol address:

1600 Pennsylvania Avenue

Washington, D.C. 20500

Phone: (202) 456-1414

www.whitehouse.gov

U.S. SENATE

CHARLES SCHUMER (D)

Capitol address:

322 Hart Senate Office Bldg.

Washington, D.C. 20510

Phone: (202) 224-6542

District address:

One Park Place, Suite 100

Peekskill, NY 10566

Phone: (914) 734-1532

www.schumer.senate.gov

KIRSTEN GILLIBRAND (D)

Capitol address:

478 Russell Senate Office Bldg.

Washington, D.C. 20510

Phone: (202) 224-4451

District address:

P.O. Box 749, Yonkers, NY 10710

Phone: (845) 875-4585

www.gillibrand.senate.gov

U.S. HOUSE OF REPRESENTATIVES

NITA M. LOWEY (D) (17)

Capitol address:

2365 Rayburn HOB

Washington, D.C. 20515

Phone: (202) 225-6506

District address:

222 Mamaroneck Avenue, Suite 312

White Plains, NY 10605

Phone: (914) 428-1707

Rockland: (845) 639-3485

www.lowey.house.gov

SEAN PATRICK MALONEY (D) (18)

Capitol address:

2331 Rayburn HOB

Washington, D.C. 20515

Phone: (202) 225-5441

District address:

123 Grand Street, 2nd Fl.

Newburgh, NY 12550

Phone: (845) 561-1259

www.seanmaloney.house.gov

ANTONIO DELGADO (R) (19)

Capitol address:

1007 Longworth HOB

Washington, D.C. 20515

Phone: (202) 225-5614

District address:

256 Clinton Ave

Kingston, NY 12401

Phone: (845) 443-2930

https://delgado.house.gov

STATE ELECTED OFFICIALS

LOB indicates: Legislative Office Building

188 State Street, Albany, NY 12247

GOVERNOR

ANDREW M. CUOMO (D)

State Capitol Building

Albany, NY 12224

Phone: (518) 474-8390

www.governor.ny.gov

COMPTROLLER

THOMAS P. DINAPOLI (D)

Albany Office

110 State Street, Albany, NY 12236

Phone: (518) 474-4044

contactus@osc.state.ny.us

STATE SENATE

SHELLEY B. MAYER (D, WF) (37)

District address:

222 Grace Church Street, Suite 300

Port Chester, NY 10573

Phone: (914) 934-5250

Capitol address:

LOB: Room 509

Phone: (518) 455-2031

www.nysenate.gov/senators/shelley-b-mayer

smayer@nysenate.gov

DAVID CARLUCCI (D) (38)

District address:

20 South Main Street

New City, NY 10956

Phone: (845) 708-7701

Capitol address:

LOB: Room 514

Phone: (518) 455-2991

www.nysenate.gov/senators/david-carlucci

carlucci@nysenate.gov

JAMES SKOUFIS (D) (39)

District address:

47 Grand Street

Newburgh, NY 12550

Phone: (845) 567-1270

Fax: (845) 567-1276

Capitol address:

LOB: Room 815

Phone: (518) 455-3290

www.nysenate.gov/senators/james-skoufis

skoufis@nysenate.gov

PETER HARCKHAM (D, WF) (40)

District address:

1 Park Place, Suite 302

Peekskill, NY 10566

Phone: (914) 241-4600

Capitol address:

LOB: Room 812

Phone: (518) 455-2340

www.nysenate.gov/senators/pete-harckham

harckham@nysenate.gov

SUE SERINO (R) (41)

District address:

4254 Albany Post Road

Hyde Park, NY 12534

Phone: (845) 229-0106

Capitol address:

LOB: Room 613

Phone: (518) 455-2945

www.nysenate.gov/senators/sue-serino

Serino@nysenate.gov

JEN METZGER (D, WF) (42)

District address:

201 Dolson Avenue, Suite F

Middletown, NY 10940-6576

Phone: (845) 344-3311

Capitol address:

LOB: Room 817

Phone: (518) 455-2400

www.nysenate.gov/senators/jen-metzger

metzger@nysenate.gov

DAPHNE JORDAN (R) (43)

District address:

1580 Columbia Turnpike

Building 2, Suite 1

Castle-On-The-Hudson, NY 12033

Phone: (518) 371-2751

Capitol address:

LOB: Room 508

Phone: (518) 455-2381

www.nysenate.gov/senators/daphne-jordan

jordan@nysenate.gov

GEORGE AMEDORE (R) (46)

District address:

3770 Carman Rd, Store 3

Schenectady, NY 12303

Phone: (518) 913-7001

Capitol address:

LOB: Room 408

Phone: (518) 455-2350

www.nysenate.gov/senators/georgeamedore-jr/contact

JAMES L. SEWARD (R) (51)

District address:

41 South Main Street

Oneonta,NY 13820-2516

Phone: (607) 432-5524

Capitol address:

LOB: Room 414

Phone: (518) 455-3131

www.nysenate.gov/senator/james-l-seward

seward@nysenate.gov

STATE ASSEMBLY

DAVID BUCHWALD (D) (93)

District address:

100 S.Bedford Road, Suite 150

Mount Kisco, NY 10549

Phone: (914) 244-4450

Capitol address:

LOB: Room 331

Phone: (518) 455-5397

www.assembly.state.ny.us/mem/David-Buchwald

BuchwaldD@assembly.state.ny.us

KEVIN M. BRYNE (R) (94)

District address:

3 Starr Ridge Road, Suite 204

Brewster, NY 10509

Phone: (845) 278-2923

Capitol address:

LOB: Room 318

Phone: (518) 455-5783

www.nyassembly.gov/mem/Kevin-M-Byrne

Kevin-Byrne@assembly.state.ny.us

SANDRA GALEF (D) (95)

District address:

2 Church Street

Ossining, NY 10562

Phone: (914) 941-1111

Capitol address:

LOB: Room 641

Phone: (518) 455-5348

www.assembly.state.ny.us/mem/Sandy-Galef

GalefS@assembly.state.ny.us

KENNETH ZEBROWSKI (D) (96)

District address:

67 North Main Street

New City, NY 10956-3700

Phone: (845) 634-9791

Capitol address:

LOB: Room 424

Phone: (518) 455-5735

www.nyassembly.gov/mem/kenneth-zebrowski/

ZebrowskiK@assembly.state.ny.us

ELLEN JAFFEE (D) (97)

District address:

One Blue Hill Plaza, Suite 1116

POB 1549, Pearl River NY 10965-3100

Phone: (845) 624-4601

Capitol address:

LOB: Room 626

Phone: (518) 455-5118

www.assembly.state.ny.us/mem/Ellen-Jaffee

JaffeeE@assembly.state.ny.us

KARL BRABENEC (R) (98)

District address:

28 North Main Street, Suite 2

Florida, NY 10921

Phone: (845) 544-7551

Capitol address:

LOB: Room 329

Phone: (518) 455-5991

www.assembly.state.ny.us/mem/Karl-Brabenec

Brabeneck@assembly.state.ny.us

COLIN SCHMITT (D) (99)

District address:

6 Depot Street, Suite 103

Washingtonville, NY 10992

Phone: (845) 469-6929

Capitol address:

LOB: Room 433

Phone: (518) 455-5441

www.nyassembly.gov/mem/Colin-Schmitt

schmittc@nyassembly.gov

AILEEN GUNTHER (D) (100)

District address:

18 Anawana Lake Road

Monticello NY 12701-3200

Phone: (845) 794-5807

Middletown City Hall, 3rd floor

16 James Street, Middletown, NY 10940

Phone: (845) 342-9304

Capitol address:

LOB: Room 826

Phone: (518) 455-5355

www.assembly.state.ny.us/mem/Aileen-M-Gunther

GuntheA@assembly.state.ny.us

BRIAN D. MILLER (R) (101)

District address:

4747 Middle Settlement Road

New Hartford, NY 13413

Phone: 315-736-3879

14 Central Ave, Suite 101

PO Box 247

Wallkill, NY 12589

Phone: (845) 895-1080

Capitol address:

LOB: Room 544

Phone: (518) 455-5334

www.nyassembly.gov/mem/Brian-D-Miller

millerb@nyassembly.gov

CHRIS TAGUE (R) (102)

District address:

45 Five Mile Woods Road, Bldg 2, Suite 2

Catskill, NY 12414

Phone: (518) 943-1371

Capitol address:

LOB: Room 937

Phone: (518) 455-5363

www.assembly.state.ny.us/mem/Chris-Tague

taguec@nyassembly.gov

KEVIN CAHILL (D) (103)

District address:

Governor Clinton Building

One Albany Avenue, Suite G-4,

Kingston NY 12401-2946

Phone: (845) 338-9610

Capitol address:

LOB: Room 716

Phone: (518) 455-4436

www.assembly.state.ny.us/mem/Kevin-A-Cahill

CahillK@assembly.state.ny.us

JONATHAN JACOBSON (104)

District address:

47 Grand Street

Newburgh, NY 12550

(845) 562-0888

Capitol address:

LOB: Room 628

Albany, NY 12248

Phone: (518) 455-5762

www.nyassembly.gov/mem/Jonathan-G-Jacobson

jacobsonj@nyassembly.gov

KIERAN LALOR JR. (R) (105)

District address:

North Hopewell Plaza, Suite #1

1075 Rt. 82, Hopewell Junction, NY

12533

Phone: (845) 221-2202

Capitol address:

LOB: Room 531

Phone: (845) 221-2202

www.assembly.state.ny.us/mem/kieran-michael-lalor

LalorK@assembly.state.ny.us

DIDI BARRETT (D) (106)

District address:

12 Raymond Avenue, Suite 105

Poughkeepsie, NY 12603

Phone: (845) 454-1703

Capitol address:

LOB: Room 841

Phone: (518) 455-5177

www.assembly.state.ny.us/mem/didi-barrett

BarrettD@assembly.state.ny.us

COUNTY EXECUTIVES

DUTCHESS COUNTY

MARCUS J. MOLINARO (R)

County Executive’s Office

22 Market Street

Poughkeepsie, NY 12601

Phone (845) 486-2000

countyexec@dutchessny.gov

ORANGE COUNTY

STEVEN M. NEUHAUS (R)

Orange County

Government Center

255 Main St.

Goshen, NY 10924

Phone: (845) 291-2700

ceoffice@orangecountygov.com

PUTNAM COUNTY

MARYELLEN ODELL (R)

Putnam County Office Building

40 Gleneida Avenue, 3rd Floor

Carmel, New York 10512

Phone: (845) 808-1001

PutnamCountyExecutive@

putnamcountyny.gov

ROCKLAND COUNTY

EDWIN J. DAY (R)

Office of County Executive

11 New Hempstead Road

New City, NY 10956

Phone: (845) 638-5122

CountyExec@co.rockland.ny.us

SULLIVAN COUNTY

MANAGER

JOSHUA POTOSEK

Sullivan County

Government Center

100 North Street, PO Box 5012

Monticello, NY 12701-5012

Phone: (845) 807-0450

ULSTER COUNTY

PATRICK RYAN (D)

244 Fair Street

Kingston, NY 12401

Phone: (845) 340-3800

exec@co.ulster.ny.us

WESTCHESTER COUNTY

GEORGE LATIMER (R)

900 Michaelian Building

148 Martine Avenue, Suite 408

White Plains, NY 10601

Phone: (914) 995-2900

ce@westchestergov.com

BUSINESS ASSOCIATIONS

NATIONAL ASSOCIATION OF MANUFACTURERS

1331 Pennsylvania Avenue

Washington, DC 20001

Phone: (202) 637-3182

www.nam.org

manufacturing@nam.org

MANUFACTURERS ALLIANCE OF NEW YORK (MANY)

5788 Widewaters Parkway

Syracuse, New York 13214

Phone: (315) 474-4201

www.macny.org

NEW YORK STATE BUSINESS COUNCIL

152 Washington Avenue, Suite 400

Albany, NY 12210

Phone: (518) 465-7511

www.bcnys.org

MANUFACTURING & TECHNOLOGY ENTERPRISE CENTER (MTEC)

180 South Street, Bldg 1, Suite 1

Highland, NY 12528

Phone: (845) 391-8214

www.mfgtec.org

UPSTATE VENTURE ASSOCIATION OF NEW YORK (UVANY)

1971 Western Avenue, Suite 1110

Pittsford, New York 14534

Phone: (518) 320-2746

www.uvc.org

ROCKLAND BUSINESS ASSOCIATION, INC.

One Blue Hill Plaza, P.O. Box 1567

Pearl River, NY 10965

Phone: (845) 735-2100

www.rocklandbusiness.org

THE BUSINESS COUNCIL OF WESTCHESTER

800 Westchester Avenue, Suite S-310

Rye Brook, NY 10573

Phone: (914) 948-2110

www.thebcw.org

DUTCHESS COUNTY REGIONAL CHAMBER OF COMMERCE

One Civic Center Plaza, Suite 400

Poughkeepsie, NY 12601

Phone: (845) 454-1700

www.dcrcoc.org

ORANGE COUNTY CHAMBER OF COMMERCE

40 Matthews Street, Suite 104

Goshen, NY 10924

Phone: (845) 457-9700

www.orangeny.com

NEW PALTZ REGIONAL CHAMBER OF COMMERCE

257 Main Street

New Paltz, NY 12561

Phone: (845) 255-0243

www.newpaltzchamber.org

ULSTER COUNTY CHAMBER OF COMMERCE

214 Fair Street

Kingston, NY 12401

Phone: (845) 338-5100

www.ulsterchamber.org

EDUCATION & TRAINING

BEACON INSTITUTE CLARKSON UNIVERSITY

199 Dennings Avenue

Beacon, NY 12508

Phone: (845) 838-1600

www.bire.org

MARIST COLLEGE

3399 North Road

Poughkeepsie, NY 12601

Phone: (845) 575-3000

www.marist.edu

MOUNT ST. MARY COLLEGE

330 Powell Avenue

Newburgh, NY 12550

Phone: (845) 561-0800

www.msmc.edu

SUNY NEW PALTZ

1 Hawk Drive

New Paltz, NY 12561

Phone: (845) 257-7869

www.newpaltz.edu

DUTCHESS COUNTY COMMUNITY COLLEGE

53 Pendell Road

Poughkeepsie, NY 12601

Phone: (845) 431-8000

www.sunydutchess.edu

ORANGE COUNTY COMMUNITY COLLEGE

115 South Street

Middletown, NY 10940

Phone: (845) 344-6222

www.sunyorange.edu

ROCKLAND COMMUNITY COLLEGE

145 College Road

Suffern, NY 10901

Phone: (845) 574-4000

www.sunyrockland.edu

SUNY SULLIVAN

112 College Road

Loch Sheldrake, NY 12759

Phone: (845) 434-5750

www.sunysullivan.edu

SUNY ULSTER

491 Cottekill Road

Stone Ridge, NY 12484

Phone: (845) 687-5000

www.sunyulster.edu

WESTCHESTER COMMUNITY COLLEGE

75 Grasslands Road

Valhalla, NY 10595

Phone: (914) 606-6600

www.sunywcc.edu/pdc

DUTCHESS COUNTY BOCES

5 Boces Road

Poughkeepsie, NY 12601

Phone: (845) 486-4800

www.dcboces.org

ORANGE/ULSTER BOCES

53 Gibson Road

Goshen, NY 10924

Phone: (845) 291-0100

www.ouboces.org

PUTNAM/ NORTHERN WESTCHESTER BOCES

200 Boces Drive

Yorktown Heights, NY 10598-4399

Phone: (914) 245-2700

www.pnwboces.org

ROCKLAND BOCES

65 Parrott Road

West Nyack, NY 10994

Phone: (845) 627-4700

www.rocklandboces.org

ULSTER BOCES

Rt. 9W, PO Box 601

Port Ewen, NY 12466

Phone: (845) 331-5050

www.ulsterboces.org

SOUTHERN WESTCHESTER BOCES

17 Berkley Drive

Rye Brook, NY 10573

Phone: (914) 937-3820

www.swboces.org

ECONOMIC DEVELOPMENT

NEW YORK STATE ECONOMIC DEVELOPMENT COUNCIL

111 Washington Avenue, 6th Floor

Albany, NY 12210

Phone: (518) 426-4058

www.nysedc.org

HUDSON VALLEY ECONOMIC DEVELOPMENT CORPORATION

10 Matthews St.

Goshen, NY 10924

Phone: (845) 220-2244

www.hvedc.org

TH!NK DUTCHESS ALLIANCE FOR BUSINESS

3 Neptune Road, Suite 821

Poughkeepsie, NY 12601

Phone: (845) 463-5400

www.thinkdutchess.com

THE ORANGE COUNTY PARTNERSHIP

40 Matthew Street, Suite 108

Goshen, NY 10924

Phone: (845) 294-2323

www.ocpartnership.org

PUTNAM COUNTY ECONOMIC DEVELOPMENT CORPORATION

40 Gleneida Avenue

Carmel, NY 10512

Phone: (845) 808-1021

www.putnamedc.org

ROCKLAND ECONOMIC DEVELOPMENT CORP.

Two Blue Hill Plaza, PO Box 1575

Pearl River, NY 10965

Phone: (845) 735-7040

www.redc.org

ULSTER COUNTY ECONOMIC DEVELOPMENT ALLIANCE

PO Box 1800

244 Fair Street

Kingston, NY 12402-1800

Phone: (845) 340-3000

www.ulstercountyny.gov

WESTCHESTER COUNTY OFFICE OF ECONOMIC DEVELOPMENT

148 Martine Avenue

White Plains, NY 10601

Phone: (914) 995-2000

www.westchestergov.com/public_html/index.php

WORKFORCE DEVELOPMENT INSTITITUTE

15 Stone Castle Road, Rock Tavern, NY 12575

Phone: (845) 567-1213

120 Saw Mill Road, Hastings, NY 10706

Phone: (914) 231-9670

wdiny.org

WORKFORCE INVESTMENT BOARDS

DUTCHESS ONE STOP CAREER CENTER

191 Main Street

Poughkeepsie, NY 12601

Phone: (845) 473-9000

www.dutchessonestop.org

ORANGE WORKS CAREER CENTER

3 Washington Center, 4th Floor

Newburgh, NY 12550

Phone: (845) 568-5090

33 Fulton Street 2nd Floor

Middletown, NY 10940

www.orangecountygov.com/352/Employment-Training

WESTCHESTER/PUTNAM CAREER CENTER NETWORK

120 Bloomingdale Rd.

White Plains, NY 10605

Phone: (914) 995-3910

www.westchesterputnamonestop.com

ULSTER WORKS

521 Boces Lane

Kingston, NY 12401

Phone: (845) 443-8066

www.ulsterworks.com

SULLIVAN COUNTY ONE STOP

100 North Street

Monticello, NY 12701

Phone: (845) 794-3340

sullivanny.us/Departments/Workforcedevelopment

FEDERAL AGENCIES

ENVIRONMENTAL PROTECTION AGENCY

290 Broadway

New York, NY 10007-1866

Phone: (212) 637-5000

www.epa.gov

U.S. DEPARTMENT OF LABOR

200 Constitution Ave NW

Washington, DC 20210

Phone: 1 (866) 487-2365

www.dol.gov

OCCUPATIONAL SAFETY & HEALTH ADMINISTRATION (OSHA)

401 New Karner Road, Suite 300

Albany, NY 12205-3809

Phone: (518) 464-4338

www.osha.gov

U.S. DEPARTMENT OF COMMERCE

707 Westchester Avenue, # 209

White Plains, NY 10601

Phone: (914) 682-6712

www.export.gov/newyork/westchester

U.S. SMALL BUSINESS ADMINSTRATION

26 Federal Plaza Suite 3108

New York, NY 10278

Phone: (212) 264-1450

www.sba.gov/offices/regional/ii

STATE AGENCIES

EMPIRE STATE DEVELOPMENT

625 Broadway

Albany, New York 12207

Phone: (518) 292-5100

www.empire.state.ny.us

Regional office:

33 Airport Center Drive, Suite 201

New Windsor, NY 12553

Phone: (845) 567-4882

www.empire.state.ny.us/MidHudson.html

ENVIRONMENTAL CONSERVATION

625 Broadway

Albany, NY 12233

Phone: : (518) 402-8044

www.dec.ny.gov

Regional office:

21 South Putt Corners Road

New Paltz, NY 12561

Phone: (845) 256-3000

Fax: (845) 255-0714

www.dec.ny.gov/about/558.html#region3

LABOR

Building 12 W.A. Harriman Campus

Albany, NY 12240

Phone: (518) 457-9000

www.labor.ny.gov

TRANSPORTATION

50 Wolf Road

Albany, NY 12232

Phone: (518) 457-6195

Regional office:

4 Burnett Blvd.

Poughkeepsie, NY 12603

Phone: (845) 431-5700

www.dot.ny.gov/regional-offices/region8/contacts

TECHNICAL SOCIETIES

ACM Association for Computing Machinery

pok.acm.org

APICSTZ APICS Tappan Zee

www.apicstz.org

ASQ ASQ Mid-Hudson Section 302

www.asqmidhudson.org

ASSE American Society of Safety Engineers

Hudson River Valley Chapter

hudsonrivervalley.asse.org

HVOPEN HV Open (previously MHVLUG)

Open Technologies

hvopen.org

HVP Hudson Valley Programmers

www.meetup.com/hvprogrammers/

IEEE Mid-Hudson Section of the IEEE

webinabox.vtools.ieee.org/wibp_home/index/R10019

MHCUG Mid-Hudson Computer User Group, Inc.

www.mhcug.org

MHHRA Mid-Hudson Human Resource Association

www.midhudsonhr.org

MHVSHRM Mid-Hudson Valley Society for Human Resource Management

www.mhvshrm.org

PMA Precision Metalforming Association of NY and NJ

www.pma.org/districts/NY/

PMI Project Management Institute

www.pmihvc.org

SME Society of Manufacturing Engineers

www.sme.org

SWE Society of Women Engineers

www.swe.org

WiM Women in Manufacturing

www.womeninmanufacturing.org

The Certainty Of Uncertainty

ENTERPRISE RISK MANAGEMENT

IGNITION LIFE SOLUTIONS | BY SRI VILAYANOOR

ERM-101: A PRIMER

SETTING THE CONTEXT: UNCERTAINTY

Imagine you had a magic wand and your wish of going back to the summer of 2019 came true.

If I had told you then that we are going to be faced with a global pandemic in just a few months – something that would bring the world to a brief stand-still and when we do recover, we would live in a completely new norm – what would have been your response? “There goes another conspiracy theory” would be my guess — or something close to that! While it is debatable, whether or not the COVID-19 crisis was predictable based on intelligence available through several independent sources like the National Institute of Health (NIH). What is clear from our experience is this: as human beings in a free society, the general tendency is to underestimate the adverse impact of uncertainties from “what we don’t know we don’t know”.

UNCERTAINTY IS A FACT OF LIFE.

There literally cannot be anything that we can be 100% sure about. From betting on the outcome of a game of cards to projecting your personal/business revenues to even day-to-day tasks like being just-in-time for a meeting – there is an inbuilt level of uncertainty in literally anything we can think of. It is one of those things from which you can try to run, but never hide. But, why try to hide from uncertainty when there is a proven way to manage it? The concept of risk management has been around from time immemorial and provides an effective framework for managing uncertainty and its impact.

DEFINITION OF RISK:

The term “risk” has been the center point of discussions on several platforms for a very long time. From Einstein’s Theory of Relativity and Heisenberg’s Uncertainty Principles to stochastic modelling that drives your Google Map algorithms, the concept of risk has attracted an almost infinite range of applications. The search of a consistent definition of the term “risk” will lead us to the conclusion that there are several definitions available based on the context. The one that I personally like is the definition of risk from the International Organization for Standardization’s (ISO) Guide 73:2009. This internationally accepted Standard defines risk as the “effect of uncertainty on objectives.” Among all definitions I have come across, this fits the KISS principle – it is simple, short and demystified! It is not the actual uncertainty that is the risk – risk is the impact of the uncertainty on what you are trying to achieve! What’s interesting is that when ISO published it’s “ISO 9000:2015, Quality management systems–Fundamentals and vocabulary”, the phrase “deviation from the expected, positive or negative” was added to describe the Guide 73 definition about “effect of uncertainty”. Yes – as one can imagine, uncertainty does not always have to yield an adverse impact on our objectives; it can also contribute to the achievement of our objectives. The accelerated growth of online shopping portals like Amazon and digital business communication apps like Microsoft Teams and Zoom since the start of the COVID-19 pandemic illustrate the positive impact of uncertainty on objectives.

THE CASE FOR MANAGING RISK AT THE ENTERPRISE LEVEL:

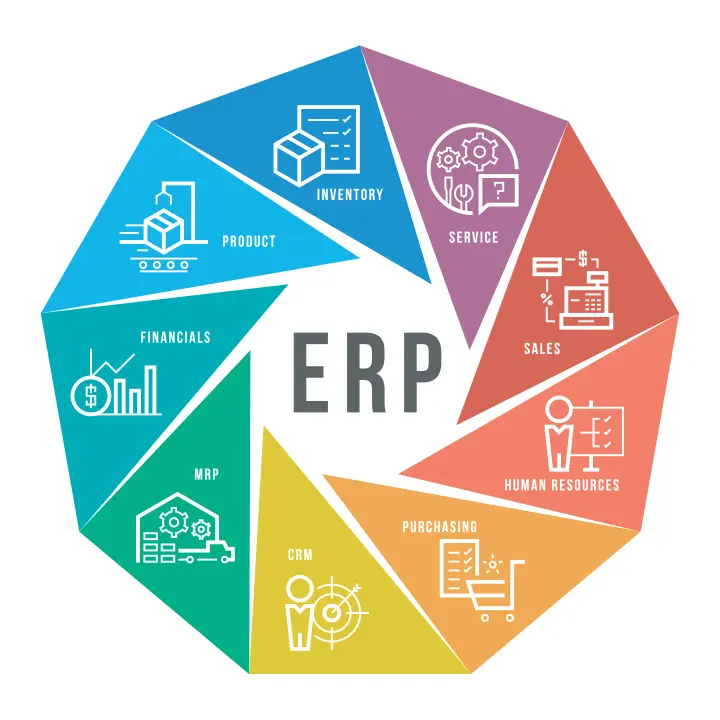

If risk management is the business of managing the impact of an uncertainty on our objectives, the initial response we normally get goes something like this: “we do that already!” Yes – the crux of any manager or leader’s job description is to predict and proactively prevent undesirable events. While this allows for a siloed approach to managing risks in one’s individual function, it does not allow for consideration of risks outside the specific function. For instance, let’s take two managers to illustrate this common pitfall: a Purchasing Manager and an Engineering Manager.

The Purchasing Manager wants to install an Enterprise Resource Planning (ERP) system upgrade to reduce missed shipments from suppliers. The Engineering Manager, on the other hand, is keen on investing in a Digital Work Instruction module to reduce human error in manufacturing. Extrapolate this thinking to other functions of the organization – and you can only imagine the wish-list from each functional manager with the right intent to manage risks at their individual functional levels. While every manager’s ask is valid, an enterprise with limited resources – financial and otherwise – has to deal with the challenge of prioritizing the most important investments in pursuit of the enterprise’s objectives. During a recent presentation of this concept, a client of mine asked me in a satirical tone: “You mean, I can’t go with the dude that yells the loudest?” We laughed about it, but deep within, I was just thinking that’s not far from reality in a lot of organizations. Allocation of resources to prevent undesirable events without objectivity and independence can result in a range of problems – some minor, while others catastrophic. This is where the siloed approach to risk management fails and paves the road for an Enterprise Risk Management (ERM) model. The ERM model would allow for a single-view comparison of the risks presented by the Purchasing, Engineering and other individual functions. The result would be the prioritization of resource allocation required for the enterprise as a whole to pursue it’s objectives.

DEMYSTIFYING ERM – THE BASIC FRAMEWORK:

Enterprise Risk Management (ERM) is an extremely commonsense driven model. When you are faced with a task of preparing for an uncertainty, what would your natural instincts drive you to do? You would first want to know what are the possible uncertain events that can come your way. The term “possible” is interesting and is deliberately chosen for this context. Naturally, you cannot possibly list all possible uncertain events – but a good faith effort towards that end will challenge you to use cross-functional teams with diverse experience about the subject matter. Once you have identified foreseeable uncertain events, you would want to somehow prioritize the list, so you can focus on the vital few risks that would otherwise stop you from meeting your objectives. This would be the equivalent of choosing the battles you want to win/lose with an eye on winning the war – the battles being the risks and the war being the enterprise’s objectives.

The above common-sense driven thinking can be summarized in the following three sequential steps:

- RISK IDENTIFICATION

Ask “What could go wrong”? - RISK VALIDATION

Ask “So what? If it went wrong, what’s the worst-case impact? Can I accept it in pursuit of my objectives or not? - RISK RESPONSE

Ask “Now what? In other words, what do I do about it?”

While the scope of this article does not allow us to delve deep into the mechanics within each step, let us make an attempt to throw some light into some key aspects to be considered.

RISK IDENTIFICATION:

It is not uncommon to see organizations recognize the impact of uncertainties after an undesired event hits us (ex. a customer recall, losing a key employee to competition or a regulatory lapse). As an alternate to this reactive model, a deliberate proactive effort to scan internal and external factors that could impact a business is the key to effective risk identification. Although a wide range of tools to aid the risk identification exercise is available, an organization must carefully choose methods that align well with their business model and culture. For all that you know, your organization may already be using a few effective tools that can be repurposed for your enterprise level risk identification exercise. For instance, with some effort, several traditionally used continual improvement tools like Value Stream Mapping (VSM) and Failure Modes & Effects Analysis (FMEA) can be adapted to help identify internal risks.

Organizations that are not too complex can probably get away with even simpler tools for risk identification like brainstorming and the use of simple questionnaires & surveys. While these tools can work effectively to identify internal risks, risks that can occur due to factors outside an organization cannot be ignored. An easy way to remember some key external risks is the PESTEL acronym – Political, Economic, Social, Technological, Environmental and Legal risks. Depending on the complexity of an organization’s business model, its products and technology impact, identification of external risks can be challenging. The use of SWOT analyses, competitive intelligence, benchmarking and environmental studies are some tools to consider for external risk identification.

RISK VALIDATION:

Once identified risks are consolidated in a single dashboard view, the task at hand is to assess the impact of each risk event on an organization’s ability to meet objectives. The idea of risk appetite is a useful thought process in this exercise. Let us face it – unless you have infinite resources, it is not practical to try and respond to everything that can go wrong. You have got to pick your battles. In this context, ask yourself what is the maximum risk you are willing to accept in pursuit of your objectives? Once articulated, this becomes your risk appetite. The mechanics of how to articulate an organization’s risk appetite is the subject for another article, however, at this point, it is safe to assume that risk-averse organizations have lower appetites for risk acceptance than their risk-hungry counterparts. Comparison of each identified risk against an organization’s risk appetite allows for classification of the risks into two broad buckets: risks that are lower than your risk appetite; and those that are higher.

RISK RESPONSE:

The heavy lift is done by now – you know which risks are below and above your appetite. “Now What?” In the simplistic model, you accept the risks below your appetite in pursuit of your objectives. What do you do with the one’s that are above your appetite?

You cannot accept it, of course! Ready for another acronym? You can TAM your unacceptable risk – Transfer, Avoid or Mitigate it. While increasing your insurance coverage is an example of transferring your risk to another entity that is willing to accept it, the concept of risk avoidance would require you to stop engaging in any activities that can result in the particular risk. Mitigating a risk is where you engage in continual improvement initiatives to bring the risk below your appetite. Lean, Six Sigma and other problem-solving tools come in handy for this option. Post implementation reviews to ensure long term effectiveness of the risk response actions must be completed diligently.

CONCLUSION:

Seamlessly embedding the ERM process within an organization’s strategic planning and operational monitoring activities will enable an organization to manage uncertainties in pursuit of enterprise objectives. Such organizations are generally better prepared to deal with uncertainties compared to organizations that do not have an enterprise-level framework for managing risks.

The intent of this article is to serve as a demystified primer for the vast domain of Enterprise Risk Management (ERM). There are several other aspects of this critical subject matter that must be discussed and understood before one can start effectively leveraging benefits. Impact of organization structures, governance model, role of internal audits, development of the enterprise risk-registry, articulating consistent risk appetite, exploiting opportunities from uncertainties, information technology & related security concerns, business continuity and disaster recovery programs are some areas that need further coverage. The author hopes to continue this discussion on this topic in successive upcoming interactions to support the interested reader’s efforts in building a robust ERM framework in pursuit of enterprise objectives.

Sri Vilayanoor is the President/CEO of Ignition Life Solutions, Inc. Management systems consulting firm. He has an MS in Industrial Engineering and BS in Mechanical Engineering.

Company Profile of PTI

COMPANY PROFILE:

PTI (PACKAGING TECHNOLOGIES & INSPECTION) | By Taylor Dowd

PASSIONATE ABOUT QUALITY

Brothers Oliver and Julian Stauffer are senior executives at their family-owned business, PTI (Packaging Technologies & Inspection). As they have taken complete control of the company and grown in their respective professional journeys, Oliver and Julian have found some of their greatest success comes simply from following the company’s values.

On the walls of PTI’s Westchester headquarters hangs a board with these five core values, which have become a symbol of what the company strives to be, a reminder for its workforce and leaders: communicate, do what you say you will do, sound engineering through good science, be passionate about quality, care for others. Those values drive every decision we make,” says Oliver.

The company manufactures test equipment for high risk package testing. Its equipment goes to a production facility or laboratory where nondestructive testing is performed on container closure systems to determine the integrity of the product. PTI is also the North American agent for Waldner, the packaging systems distribution division. A separate entity, Waldner manufactures equipment in Germany and distributes it in the U.S.

PTI services clients in the food and pharmaceutical industries. Benchtop test equipment goes into a laboratory where production line operators test the products to ensure they meet the acceptable standards. PTI has five core technologies: pressure decay, vacuum decay, airborne ultrasound, force decay and high voltage leak detection. In packaging laboratories, this method of testing also aids in advancing the development and design process.

Since its inception PTI has worked to create patented sensory technologies, which have evolved from benchtop systems to inline automated inspection solutions that companies can install into production lines for product inspection.

Today, daily operations at PTI are primarily focused on R&D, marketing, sales and test equipment assembly. Mechanical engineers, electrical engineers, programmers and sensory development scientists work in the 14,500 sq. ft. facility on both the manufacturing and assembly sides of the business. There are three CNC machines and other precision manufacturing equipment on site.

How It All Started

Tony is the founder of PTI and Oliver and Julian’s father.

An engineer at heart, Tony began the company in Tuckahoe, NY in 1985 with Heinz Wolf, who has been with the company ever since, and Lisa Wray, a bookkeeper. Initially, the business focused on importing Swiss-made inspection equipment and manufacturing high precision equipment.

Packaging eventually became the core focus, as the company solely distributed equipment from Europe.

In the early ‘90s, Tony moved the business to a larger facility and began manufacturing inline container testing systems, which it manufactured and distributed directly.

They continued distributing leak testing systems through the late ‘90s, when they began designing their own leak testing technology. The company manufactured and sold leak detection systems. Waldner filling and sealing equipment began to take off, as its product line became the primary product being distributed.

In 2000, the Waldner packaging division became an integral partner with PTI, as the inspection processes continued to grow. It became the focal point of the business and generated a majority of company profits. The inspection side was still largely undeveloped until Tony began developing new technologies. Today, the inspection team at PTI has 55 employees. Inspection technologies are what Julian calls the “heart and soul of our company.”

The CEO

Oliver studied environmental science as an undergrad and completed a summer internship with PTI. His background in science allowed him to implement more scientific-based principles in an otherwise engineering-focused business. He is not an engineer by trade; he learned everything from his dad. After taking a sabbatical following graduation, he returned home and joined the company in 2005, beginning in R&D.

Failure has played a massive role in Oliver’s professional growth.

In 2008, he developed a patented sensory technology; however, the project ultimately failed. Oliver explains the failure was a challenge, but more importantly a learning experience. He learned the importance of developing fail-safe technologies, providing superior client support, and what it takes to create a successful business.

“Never lose a good opportunity to learn from your mistakes and be resilient in your response”, says Oliver. He attended business school afterwards before continuing his work at PTI.

The COO

Prior to Julian’s employment at PTI, he worked as an industrial engineer for a Stanley Black & Decker manufacturing plant in Texas. He took a sabbatical in Central America with plans to stay for at least a year. When he received a call from his dad encouraging him to consider the future of PTI, Julian made the decision to return home after six months to try out the family business. Satisfied with his experience in the corporate world, Julian joined PTI in 2010.

He began as a service engineer, then advanced to working on and selling products to major food companies across the U.S.

Julian took leadership and development courses and became involved with the packaging technology side of the business. His contributions to several major projects from start to finish kick started fast rising success at the company.

Working with Family

Working for a family company means being entrusted with responsibilities in a safe environment. Reaching success becomes more possible with the help of accessible coaching and learning directly on the job. Julian and Oliver were able to learn firsthand about business from real industry exposure.

They are humored by their father’s repetitive advice, and they acknowledge that the habit has instilled important information from him. “We went into meetings where he’s drilled the same points again and again. It engrained certain values, certain principles, certain mentalities into us,” Julian says.

At 38 and 34 years old, Oliver and Julian still receive advice from their dad frequently. Even as leaders of the business, they respect their dad’s wisdom and welcome his guidance. “I have to recognize that one day my dad will not be there. I will not have the benefit of hearing his voice say those things. That has me appreciate and take the time to listen to him on those 7:00am phone calls,” Oliver says.

They recognize the dynamic of working for family and the opportunities that come along with it. “You’re handed the keys to the vehicle far earlier than you should be handed those keys. And, you learn pretty quickly how to drive that car. We’ve been given a high level of trust but given the coaching along the way,” Oliver says. Still, they wanted to maximize their own potential for growth and success. “We didn’t want to be the children who were handed the keys to the car. We wanted to earn them.”

Both Oliver and Julian recognize how impactful their father’s relationship has been on their lives – not just professionally, but personally. Today, Tony is removed from daily operations at the business but fulfills his position as chairman of the board. He owns an affiliate operation in Europe and has since become a customer of PTI by distributing its equipment.

Part of PTI’s success comes from striking a balance between old and new leadership. While Tony is in a different role than when he started the business, he remains a special part of the company, not just for his insight as a businessman, but as a mentor and father.

Oliver hopes to “capture his voice and always have it there.” He explains part of the leadership transition is to “honor the past, be really clear about the present, and map out the future.”

The Workforce

PTI hires people from all over the world. Its workforce is composed of employees from China, India, Russia, Africa and Europe, to name just a few places. Some employees are not U.S. citizens, so the company sponsors their visas. Because Tony and Heinz both came to America on visas, Oliver and Julian recognize the importance of supporting those on that same journey.

“We want to take care of people. We want to give people the opportunity to succeed,” Julian says.

The company has employees over the age of 70. A significant portion of its workforce is under age 30 or over 50. The diversity in experience within the organization makes mentorship between the generations a key driver of success. Diverse backgrounds and various perspectives help build the company and allow different ideas and mindsets to join together to help reach decisions. Providing a collaborative work environment is part of their leadership responsibility, Oliver explains. “Julian and I have worked very hard to develop the culture we feel will create success for this company.” PTI looks for dedicated team members with strong work ethic and commitment to quality. “We have a strong appreciation for intelligence and attitude,” Julian says.

Navigating COVID-19

PTI has not seen a shift in its standard growth path since the pandemic began, and has managed to maintain its success. The company has retained its workforce and even brought on several new employees since. Oliver explains the team has been agile and remained dedicated during COVID-19. “We never stopped. We never skipped a beat. We continued to put faith in the workforce.

The goal here is not profit. It’s to get to the end of the year as one team.” Management phone calls, webinars, and an online presence have helped normalize company operations. Some employees were able to take equipment home to assemble pieces in their garages, workshops, and basements. PTI assembled part kits that allowed employees to assemble leak testers for client deliveries from the comfort of their homes.

Looking Ahead

PTI does not look to expand into a wide breadth of markets; however, the company intends to improve by developing new systems and automating its technologies. It is focused on the field of robotics and is currently building a large automated system for syringe leak detection. PTI hopes to optimize its physical space by expanding the R&D area and assembly floor. As the organization grows, making more space for the manufacturing and assembly areas will ensure there is room for all operations. Moving towards automation means the need for more warehouse space and potentially relocating.

Julian will be stepping down as COO. He acknowledges the success of the company and the leadership of its employees play a major role in his decision. “[Oliver] can handle the company just as our dad did. We’re growing so much as a company and having other people step up. It says a lot about what we’ve done,” he says.

In 2020, both executives have achieved success with the state of their family business and are content with its progression.

Ultimately, they agree that sticking to their core values is essential for leading their company. “If you deviate from those values, you’re no longer playing the game you set out to play,” Oliver says.

When it comes to making the most difficult decisions, adhering to them ensures all choices are in the company’s best interest. As PTI expands, the values will remain fundamental to growing and changing the future of the business.

Taylor Dowd is journalism graduate of SUNY New Paltz. She is now a freelance writer living in Fishkill, NY.

Business Analytics

INDUSTRY 4.0

SCHOOL OF BUSINESS SUNY NEW PALTZ | Dr. Chih-Yang Tsai

The Time Is Now To Up Your Business Analytics Capacity

IN GOD WE TRUST, ALL OTHERS BRING DATA

– W. Edwards Deming

The COVID-19 pandemic has disrupted the operation of many organizations. It is imperative for organizations to quickly respond to the shifting markets and improve internal processes. Business analytics, with many of its modeling tools, can help detect new demand patterns, identify predictive maintenance needs, or find the product mix to maximize contribution margin. For small and medium sized businesses (SMEs) it can be daunting to deploy an analytics system, especially with the plethora of jargon surrounding it, such as big data, business intelligence, analytics, machine learning, data mining, and artificial intelligence. On one hand, these businesses fear they will miss their chance to hop on the analytics bandwagon, but on the other, they are frightened because they simply do not know where to start. This discussion provides a roadmap for SMEs seeking to build a data-driven decision environment.

DRIVE OUT THE FEAR

Regardless of the jargon, those buzz terms are all about applying quantitative methods on data to extract information or knowledge.

Formally or informally, every organization must have some quantitative analyses already in decision processes, such as budgeting and quality control where decisions are made based on observed patterns.

Besides, there is often no universally agreed upon definitions of those terms. For example, some people consider Business Intelligence as the umbrella term for all other terms, while others view it on a much narrower scope, i.e., the ability to drill-down, roll-up, and chart a multi-dimensional dataset. For the purposes of this discussion, the word “analytics” will be used as a generic term for all quantitative modeling techniques applied on a dataset. When initiating changes in an organization, such as implementing an analytics system, there are often two major concerns from top management: the amount of resources needed and potential employee resistance. However, analytics can be done using tools as simple as an Excel spreadsheet or as cost effective as free open source software. Additionally, resistance is often eased as employees become more familiar with the tools. The following approaches and cases provide insights on how to overcome these two hurdles.

JUST DO IT

For beginners, learning-by-doing is a good way to soften resistance. Through “doing”, organizations nurture a data-driven decision making culture. This culture is built on trust, through engagement, which in turn stems from internal conversations on the results of quantitative analysis. The numerical result serves as a frame for the conversation. However, organizations also need to be aware of the number trap inherent in many key performance indicators (KPIs) for two reasons. First, hardly any indicator can measure the overall performance of an organization.

Obsessing with one goal could improve a specific metric but will likely lead to a sub-optimal solution for the organization as a whole. Therefore it is recommended businesses utilize a balanced scorecard approach. The second reason is, as Goodhart’s Law claims, “When a measure becomes a target, it ceases to be a good measure.” What we often see with a quota-based reward policy is people incentivized to manipulate the system. To develop a data-driven decision making culture, an organization needs to create an open and non-threatening atmosphere when discussing the quantitative result. The discussion is not about assessing the performance of a unit or an individual, but about engaging in a team effort to continuously improve the process for the benefit of the entire organization.

This culture building process is similar to the development of a Total Quality Management culture through W. Edwards Deming’s Plan-Do-Check-Act (PDCA) cycle. So, beginners can start small but keep pushing the envelope. It is also helpful to identify an enthusiast in the early stages to champion the endeavor. TYPES OF ANALYTICS Analytics methods are commonly classified into three categories, descriptive analytics (what has happened), predictive analytics (what will happen), and prescriptive analytics (what to do).

Dashboard and statistical control charts are examples of descriptive analytics. Demand forecasting is an example of predictive analytics where a model identifies the pattern from the historical data and uses it to project future movement. Prescriptive analytics aims at providing a decision for action, for example, “make or buy?” Prescriptive analytics also includes optimization models that find the best decision to achieve a prescribed goal, given some constraints. For example, a product mix decision determines how many of each product to produce in order to maximize total contribution margin while meeting certain requirements and satisfying resource limitations.

A common mistake for starters is asking “what can a model do for us?” instead of “what do we want a model to do for us?”

USEFUL EXCEL TOOLS

Beyond basic data organization, processing, and charting functions, Excel has many powerful functions and add-in’s suitable for business analytics including (1) pivot tables: a multi-dimensional data aggregation tool, similar to the drill-down, roll-up function in Business Intelligence, (2) financial functions: useful for investment decisions, (3) statistical functions: distribution functions good for running simulation studies, (3) the Analysis ToolPak add-in: which includes statistical tools for descriptive analytics and regression functions for predictive analytics, and (4) the Solver add-in: an optimization problem solver for prescriptive analytics.

CASE 1: AN INCREMENTAL APPROACH

A company operates a fleet of sixty small vans to replenish its vending machine merchandise located across several cities. The company currently leases most of its vehicles. Because the leasing company covers all recurring and incidental expenses, managers prefer this risk-free option with a predictable cash outflow. However, relatively low interest rates have prompted the company to consider the buy option and in fact it even purchased several vehicles in recent years. As there has never been a formal evaluation of the two options, the company now wishes to use an analytical approach to drive its decision-making process. In its first effort, the company estimated the average cash inflows and outflows for the two options by vehicle ages and used the estimates to calculate the net present value (NPV) of each option under a range of capital cost rates. An Excel spreadsheet organizes the expected cash flows and calculates the NPVs using the built-in NPV function (Figures 1 & 2).

The initial model indicates the buy option is a better choice within most of the range of capital costs. During a discussion of the findings, the financial manager raised an issue that the average expense approach did not consider the risk of unexpected surges of vehicle maintenance cost, which may strain the company’s cash balance. Thus, in stage two, the average maintenance cost estimate was replaced by another estimate obtained from a forecasting model on the age of vehicles, which incorporated a risk factor measured by the standard deviation of the expected maintenance cost. The updated model demonstrated that when the size of owned vehicles increases, the overall risk is reduced. Hence, the buy option is still a better choice under an acceptable risk level. In the next stage, the company plans to build a fleet level decision model that minimizes total fleet cost by finding the best mix of owned and leased vehicles, subject to a cash outflow constraint and a risk tolerance constraint. This incremental approach not only advanced the company’s analytics capability, but also motivated employee buy-in through engagement. A small project such as this provides an excellent starting point due to its clear objective and limited scope.

ASK THE RIGHT QUESTION

A common mistake for starters is asking “what can a model do for us?” instead of “what do we want a model to do for us?” A model is useful only when it solves our problem. So it is important to focus first on asking the right business question, and not worrying about whether there is a model to address the question or not. Chances are, there is something for every question at least to a certain degree. Given the uncertainty involved in a decision environment, anything that sheds some insight on the issue is better than a wild guess. Furthermore, an established PDCA process with employee participation should have a self-correction mechanism. Team members should keep challenging the answer so as to refine the questions and the models.

MOVE TO THE NEXT LEVEL

Initially, companies want to avoid over investing in software, hardware, or personnel, because they might be underutilized during the learning period. Once a company passes the introductory stage and has built up some momentum, it is time to increase the investment and accelerate the pace of development. Although Excel is a good tool to begin with, it is hard to maintain when building more sophisticated models. There are several next level options to expand an organization’s analytics arsenal. Companies wishing to minimize coding need can opt for Excel add-in packages such as Palisade’s DecisionTools Suite or cloud-based services such as Microsoft Azure, which offers drag-and-drop modeling tools. Most vendors offer trial accounts for potential customers to try out. If the company has analytics specialists, open source software like Python and R are free and powerful. Since both programming languages are popular in college curricula, there is no shortage of programmers familiar with these tools. If the company has no designated analytics/IT personnel yet, it should seek to hire or assign one person with analytics and database skills to take charge of further development.

“How can analytics enhance my company’s competitive advantage or be a competitive advantage itself?”

Because analytics relies on data, this is also the time to start working on a data strategy. The first step is to consolidate all separate data sources. The data does not need to reside on one machine, but it needs to be integrated under one framework for data integrity and security. This ensures all analyses are based on clean, consistent, and up-to-date data.

CASE 2: UP TO THE NEXT LEVEL

A company developed a spreadsheet model to allocate its annual marketing budget across products and marketing channels in order to maximize its ROI. Overtime, the spreadsheet has incorporated more and more factors which turned into chained Excel formulas spreading across 20 worksheets. The model allowed managers to adjust the budget allocations and automatically update the resulting ROI through the formulas. As this continued to grow, the company realized the spreadsheet approach had become too cumbersome to maintain. It hired a consultant to rebuild the model in R with a frontend user interface (UI) and an optimization module. The new system simplified the interface allowing users to easily adjust and experiment with different assignments through scroll bars and improved the ROI by 15 to 20 percent on average based on an initial assignment by the managers.

CONCLUSION

Companies routinely collect transactional and process data.

Manufacturers in particular, have a great amount of process data generated from their machines and quality control measures. This data is a great starting point for analytics projects because process data tends to have less noise compared to market data. For example, analytics models have been used to analyze a machine’s vital signs for preemptive maintenance. With more IoT devices adding to the equation, manufacturers without a data strategy may be overwhelmed by too much data, while also being frustrated by the lack of analyticsbased insights.

Creating a data-driven decision making culture is not something that can be achieved overnight by acquiring software, hardware, or specialists. SMEs can overcome the two hurdles by following the roadmap discussed. Once you have established that culture, you are equipped to address the big question, “How can analytics enhance my company’s competitive advantage or be a competitive advantage itself?”

Dr. Chih-Yang Tsai has a Ph.D in Operations Research and is a professor of Operations and Decision Sciences in the School of Business at SUNY New Paltz since 1993.

Emerging Leader Fall 2020

MANUFACTURING LEADERSHIP

Conor McGarry, Plant Manager Zumtobel Lighting | WITH JOHNNIEANNE HANSEN

LIGHTING THE WAY

The Council of Industry’s certificate in manufacturing leadership (CML) is a cornerstone program of our association. We thought we would follow-up with a recent graduate of the program to learn more about them, their role in their company and what, if anything they took away from the program. In this article Council of Industry Vice President Johnnieanne Hansen interviews 2015 CML graduate Conor McGarry.

JH: So why don’t you start with telling me a little bit about Zumtobel Lighting?

CH: Zumtobel Lighting is a global company, here in the U.S. we manufacture lighting fixtures for the commercial, industrial, and residential industries. We have done and continue to do major projects with some of the largest name brands in the U.S. in various industries. It can be a million-dollar project, or a four hundred dollar project depending on the size of the spec.

JH: Currently, what is your role?

CH: I’m the plant manager here. I manage day to day operations, planning head count, working with continuous improvement, productions scheduling – including a daily production meeting with each department. I also work directly with customer service to make sure they are updated with lead times or delays. I’ve been a plant manager for just over two years.

JH: Tell me how you got here, what was your high school experience like and how did you get into manufacturing?

CH: I did not have a lot of direction, on my own part, I was going through the motions. I did not see a clear picture of what I was going to do. It was more, get by with decent grades, get into a good school and it will work out.

JH: Did you have the opportunity to take engineering classes or vocational programs like BOCES?

CH: Yeah, I mean I had the opportunity, but I didn’t go. I would never want to put this on others – it was primarily my lack of direction, but the meetings that I had with counselors and family friends, topics like BOCES didn’t even come up. I knew about BOCES, but I didn’t consider myself mechanically inclined, I wasn’t the kid who spent my time tearing down and rebuilding engines for fun. When I was looking at what to do in college, I never even considered engineering, at that point I thought I wanted something interesting to me, like history.

JH: I know you went to Manhattan College, what was your major?

CH: I did three years in general studies at Manhattan College with a focus on sociology. I just couldn’t figure it out when it came to education. Maybe it was the structure of it that kept me from making it work, knowing that if I wanted to study sharks I had to learn about every fish in the ocean, which was not appealing, it was not simple for me. I wasn’t motivated enough and maybe I needed to have my back up against the wall to get motivated at that point in my life.

JH: At that point, you decided to leave school and look for a job?

How did you end up working at a machine shop?

CH: I took that route because it had been something my father did before he made his career choice, working in manufacturing.

My grandfather had been heavily involved in it too, with a company in Poughkeepsie that is no longer around.

When I started in the workforce, I knew I had to be aggressive about it. I was determined not to move backwards and was looking for a job that had potential.

JH: It seems like you hit the ground running, considering you didn’t have any machine shop experience. How did you manage to break into the industry?

CH: When I started in the machine shop, I think my perception was, okay, I’m not the most experienced or talented on the machine but I was certainly the guy that they could rely on. I saw a lot of talent around me, but not really the drive to advance. The people at the shop seemed to be satisfied with where they were.

Partly because I was young, I saw the opportunity and I was a little more aggressive about it. Being eager and assertive earned me some leadership roles with that first company.

After two years I was looking for a new opportunity and ended up at Zumtobel in the machine shop. I saw the same kind of scenario; people were content but there were opportunities to grow.

JH: Sometimes we hear that it is difficult to change directions in this field. How did you get from the entry level machine shop to a plant manager?

CH: I remember this guy walking by who I really didn’t know, he worked in the research and development department and he said he was quitting. And I said, I’m going to wait for him to leave and walk into H.R. and tell them I want the job, not even wait for them to post it. I had taken a beginner AutoCAD class at BOCES and had some drafting experience. I got that position. It was an engineering role with new product development, I worked closely with new product development engineers. They would come up with the design, I could go to the factory, produce the parts, do a mockup and give feedback.

JH: At that point was your superpower that you had already been on the other side and that you were coming into the engineering side with that production experience?

CH: Yes, absolutely. It was having that taste of the factory and being able to bring that over to the engineering side rather than bringing in someone new who really didn’t understand or maybe was not fresh with the product or the machinery.

But yeah. And it’s pretty much the same story going into the next role.

A few years later I took a big jump into sales. I knew a position was going to be available and I wanted to pursue it, I went after that role and then spent four years doing post sales management. It was a good fit because of my technical ability and understanding of the product. It required travel all over the country and in some cases overseas. If an issue came up in the field with a contractor or an end user, I would assist either remotely or onsite and work directly with their contractors on the issue. After proving myself for a few years, I was approached with the opportunity to come back into operations as a production supervisor, it was the right time. I was in my late 20’s and I didn’t want to be traveling for the rest of my life.

Over the next few years opportunities came up as a natural progression and I’d like to think I was a logical choice for the Plant Manager position when it opened up.

I wouldn’t say I landed here – it was a combination of gaining experience, learning from those around me, and seeking opportunities. It was also a lot of hard work.

JH: In 2015, you were coming back into the operations side and beginning your leadership career, you also completed the Council of Industry’s Certificate in Manufacturing Leadership program – tell me a little about your experience.

CH: The certificate program was great. The classes were designed to take you from where you are, in some cases it’s foundational, but that is the purpose – building on what you already bring to the table. The certificate program helps you expand your perspective and provide skills to approach leadership – it is not a cookie cutter approach.

I think there is a misconception that leaders need to cater to employees – to be a good leader you just need to cater to every whim and abandon standards, expectations, goals or productivity.

That is a misunderstanding. I think it is about developing people, learning how to get the best out of them and caring enough to do so. It is about caring, not catering.

JH: What advice do you have for decision makers that are considering sending their employee to our program?

CH: Companies should send individuals who really want to understand and embrace the opportunity, people who will be open to learning and want to expand their leadership capabilities.

Leadership is more than just a role you are placed in, sometimes companies send people they are trying to change versus identifying individuals who are eager to learn, grow and lead.

JH: What course stands out in your memory?

CH: That’s easy. “Issues in Human Resources Management.” It was presented by Jackson Lewis, labor attorneys. They covered things from the legal side. If you are not in human resources, it’s possible to take it for granted or dismiss it or even get annoyed by various policies. Tom McDonough and his colleague took a difficult and possibly dry topic and made it interesting and impactful. Whenever another Zumtobel employee attends the leadership program, I always ask them about the HR class and they say the same thing, it’s like seeing behind the curtain and the trainers are great.

Also, I can’t say enough about “Fundamentals of Leadership” with Rebecca Mazin, it was helpful to begin the program with a process to identify your own leadership style. I try not to get too stuck on it because I want to be versatile and continuously improve, but sometimes it helps to understand yourself and how you approach a situation. It also gives you a frame of reference to understand the leadership styles of your peers and how they approach the same situation.

JH: In addition to the presenters and the leadership topics, what else stands out about the program?

CH: I really enjoyed meeting people from other companies.

I’ve spent most of my career at Zumtobel, and the Certificate Program gave me the opportunity to hear other manufacturing professionals share their experiences. Hearing their stories, how they manage day to day and deal with people, it was very interesting. Being able to interact with them on a common goal opened up my eyes to the benefits of collaboration and gave me some insight into how other places worked.

JH: 2020 took a bit of a turn back in March…

CH: Yeah, yeah, yeah. It was a roller coaster at first. It all happened quickly. Friday morning, we were shutting down until further notice. We were going to keep a few essential employees, the sales force and a skeleton crew working remotely. But the factory was shutting down. By that afternoon we were deemed essential. We called everyone back.

Since then we’ve been adjusting everyday. We are trying to be as prepared as possible, to keep the doors open and keep people safe. We made changes to the facility, spread out production lines, broke up lunch breaks to small groups. We enhanced our regular cleaning and deep cleaning, and if there was a concern even deeper cleaning, we started doing temperature tests every morning.

JH: In terms of workload, productivity, orders, how are you guys doing?

CH: From a procurement perspective, we had some difficult months, getting materials was a challenge. We have vendors in China, South America and California, it was an issue. If we were able to get the material and complete the order, it was challenging to get it out – things were on hold, job sites were on hold, if we had the order complete, we couldn’t ship it.